Winter introduces additional challenges that can alter the overall workflow on a construction site. Ground conditions change without much warning. Equipment often operates differently at lower temperatures. Material handling becomes more complex and can slow or even close down a project.

These seasonal differences can slow workflow, disrupt schedules, and increase the risk of crews redoing work. However, with a smart winter construction strategy, the nuisances of winter conditions do not have to negatively impact productivity.

Cold weather influences every decision on the worksite. Soil moisture freezes. Surface layers shift. Compaction quality changes. When teams understand these patterns, they can respond with an informed and proactive approach. Winter then becomes about anticipating conditions and understanding how the site will change.

The Science Behind Winter Conditions on a Jobsite

The first step in developing a smart winter construction strategy is understanding how the environment transforms the site. Soil responds quickly to temperature swings. Freeze-thaw cycles cause expansion and contraction that influence compaction and grading. Frozen surface layers often hide softer material below, complicating excavation and reinforcing the need for early assessments.

Equipment performance also changes in colder conditions. Machines take longer to warm up, traction is reduced, and fuel usage increases. Operators must adjust for uneven footing, reduced visibility, and longer warm-up times.

In addition to the changes in equipment performance, materials often perform differently as temperatures fall. Aggregates stiffen. Moisture becomes more difficult to manage. Concrete may not cure as expected without temperature control. These factors can compromise work that may later need to be redone.

By recognizing how winter reshapes the worksite, teams can build strategies that reinforce scheduling, sequencing, and workflow decisions. Thoughtful planning and project management begin with environmental awareness, and that awareness influences every phase of construction.

Early Planning Creates Stability All Season Long

Planning protects the worksite, reduces delays, and keeps crews organized through the season’s most unpredictable days. Early planning prepares the site with purpose and supports a proactive approach to managing winter conditions.

Drainage and grading are two of the most important tasks at the start of a successful project. Winter moisture freezes in place and creates uneven surfaces that can interfere with access, shift elevations, or complicate hauling. Stable drainage paths and smooth grades help crews remain nimble throughout the season.

Sequencing also impacts winter success. Tasks sensitive to moisture or soil movement should be completed before the first freeze. Work that tolerates colder temperatures can be scheduled later. This approach reduces the risk of redoing work caused by frozen or saturated soil.

A functional cold-weather worksite depends on strategic access planning. Snow and ice can limit mobility, so roadways and staging areas must allow for reliable movement. Well-placed storage areas protect materials and reduce time spent adjusting work processes due to frozen equipment or obstructed paths.

Planning simplifies winter, and as the environment becomes more predictable, daily operations should remain stable.

Keeping Ground Conditions Stable Through Seasonal Shifts

Soil management becomes even more critical during the winter. Ground conditions change throughout the freeze-thaw cycle, and each shift can influence compaction, trench stability, and utility placement. Effective freeze-thaw site prep maintains integrity and reduces the risk of redoing work caused by shifting subgrade.

Open excavations face the greatest risk. Frozen surface layers form a crust that can collapse or settle as temperatures rise. Moisture trapped beneath the surface weakens bedding layers or causes unexpected displacement. Crews must protect trenches, monitor backfill conditions, and adjust compaction methods to prevent shifting and maintain stable ground conditions.

Utility installation requires careful attention to soil temperature and moisture. Frozen or saturated soil can compromise alignment and long-term performance. Protective coverings and temporary insulation help maintain predictability around pipe zones and bedding layers, reducing the need to redo or re-align completed work.

Small decisions about soil protection create a cascading effect throughout the winter. Every part of the job benefits when earthwork remains stable.

Using the Right Techniques to Maintain Quality and Safety

Construction methods evolve as temperatures fall. Winter changes how teams plan, place, and protect materials. Quality remains high, and crews work with greater confidence when the approach adapts to seasonal conditions.

Concrete placement is a clear example. Without controlled curing temperatures, concrete can lose strength or develop long-term durability issues that may require redoing work in warmer months. Strategic heat and protection ensure the material sets properly.

Utility installation relies on moisture control and consistent compaction. Even minor temperature swings can change how soil behaves. Crews must adjust their processes throughout the day to maintain accuracy and efficiency.

Equipment operation also shifts. Machines take longer to reach operating temperatures. Surfaces become slick. Visibility declines at dawn and dusk. With effective communications, teams can make decisions that reduce mistakes and limit the need for corrective work.

Winter techniques are most effective when they align with the environment. A strong winter construction strategy is about working purposefully and with intent based on prevailing conditions.

Scheduling, Coordination, and Crew Safety

Cold weather shortens daylight, affects material handling, and demands quicker responses to sudden environmental changes. Scheduling becomes a practical tool that keeps teams aligned and aware of what must happen each day.

Coordination shapes winter productivity. When crews understand the plan and the sequence behind it, they adapt more easily to temperature swings or emerging weather events. Understanding the day’s objectives helps maintain progress and reduce the likelihood of redoing work caused by rushed decisions or work performed during changing winter conditions.

Safety remains essential when cold temperatures introduce new day-to-day risks, from icy walking surfaces to increased physical strain with even routine activities. By using warm-up areas, proper gear, and steady supervision, you can protect your crews and encourage strong morale. When teams know they are supported, worksites typically see higher engagement and productivity.

Winter is a season for smarter coordination. Each action supports the next. When teams communicate clearly and move with consistency, cold weather loses its ability to interrupt the pace of work.

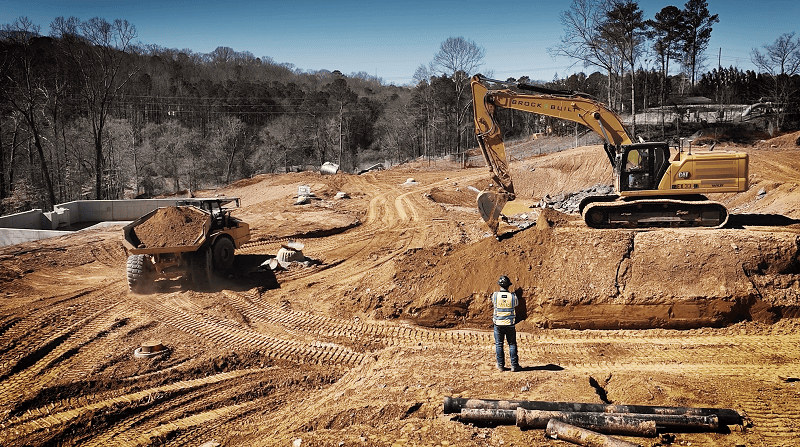

Bringing Stability and Momentum to Winter Projects

Winter work becomes more predictable when you have a team that understands how seasonal forces shape every phase of construction. Brock Civil brings decades of hands-on experience working through cold-weather conditions and planning for stable, safe, and productive sites all season long. Our crews understand how soil, materials, and equipment respond to colder temperatures, and we use that knowledge to ensure high quality and maintain timely progress.

We work closely with owners, engineers, and field teams to develop effective plans that anticipate winter challenges, site strategies that mitigate disruption, and construction methods that adapt to changing weather conditions. Our commitment to preparation, communication, and safety keeps projects moving forward—even on the coldest days.

When you choose Brock Civil, you work with a team that plans with purpose, responds to changing conditions with experience, and keeps your project moving from groundbreaking through closeout. Contact us to learn more about our expertise with cold weather projects.